A concrete, ROI-driving approach to AI in supply chain

Byline: Madhav Durbha

Implementing and measuring the success of AI in supply chain management can be daunting, thanks to the pervading AI discourse that deals in jargon, not specifics.

Business leaders can extricate themselves from this muddle of meaningless buzzwords by understanding their options and using the right type of AI to answer specific industry challenges.

This is AI diversification—a practical approach that involves investing in various AI capabilities that perform distinct but complementary functions. A dynamic portfolio of AI tools can evolve to mitigate risks and optimize decisions, delivering ROI quickly and supporting long-term resilience and profitability.

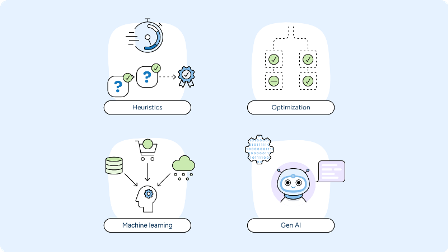

Amy Webb of NYU defines AI as "having a computer do things that normally require human intelligence." The AI algorithms that best serve supply chain purposes fall into four major categories:

- Heuristics: Heuristics are rules-based engines that simplify planning by answering requirements sequentially and eliminating options that do not meet prioritized goals. They operate well in less constrained environments, generating fast, accurate decisions. For instance, if products follow a predetermined path through a network, a company does not need to decide where to send them and can easily employ heuristics to balance lead times and batch sizes.

- Optimization: Mathematical optimization rapidly processes data to recommend decisions that best balance competing factors. Ideal for highly constrained environments requiring complex trade-offs, it weighs business objectives, like maximizing revenue or minimizing costs, against constraints like raw materials, capacity, and customer priority.

- Machine learning (ML): ML systems learn and adapt without explicit instructions, analyzing data patterns and drawing correlations between diverse data streams to make predictions. In demand planning, for example, ML algorithms process huge datasets to improve forecast accuracy and guide planning decisions. These systems compare their predictions against actual outcomes to refine calculations, improving their output the longer they are used.

- Generative AI (Gen AI): Gen AI algorithms use existing data to generate new content based on user prompts. In supply chain management, their ability to communicate complex information conversationally makes them powerful AI assistants that quickly answer user questions about planning solutions and best practices. These systems are evolving into AI copilots that can suggest company-specific recommendations and proactively help planners anticipate and minimize the impact of disruptions.

These AI algorithms should complement one another, each being used in its appropriate context. As an analogy, one could use a wrench to drive a nail into a wall, but a hammer would be a far better option. The same concept applies to a diversified AI toolkit.

With the right AI handling each task, businesses can improve efficiency, productivity, and accuracy, fulfilling customer needs while controlling inventory levels and reducing issues like obsolescence and spoilage. Strategic use of AI reduces waste for more sustainable supply chain practices and frees up working capital for wider profit margins.

By focusing on proven applications with demonstrated ROI, business leaders can quell the AI hype and instead realize AI's full potential to drive value in supply chain management.

Related Articles

The Vital Role of ATMs in South African Conveni...

Staycold International Extend Their Carbon Edit...

SAPICS announces “Innovation in Motion” theme f...